Striving for Excellence

With 70 years of metal casting history, Dameron Alloy Foundries provides expertise for your most challenging requirements. With our experienced engineering, quality and state of the art facilities, we excel as an industry leader.

Advantages

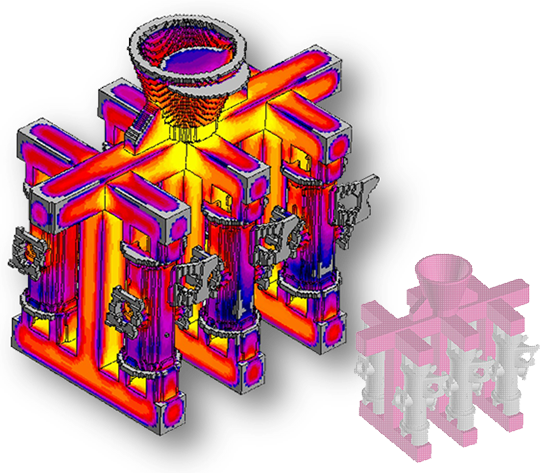

Outstanding Engineering Team:

With extensive Investment casting engineering experience, DAF is prepared to handle the most challenging of new projects. Our new product development capability is inclusive of 3D modeling, Solidification modeling and Rapid Prototype production where applicable. State of the art process control technology and practices are utilized to insure our process remains stable and consistent, so that customer quality requirements and delivery can always be achieved.

Consistent Quality System:

Dameron Alloy Foundries quality system is certified to AS9100D and ISO 9001-2015. DAFCO Aerospace has in house NADCAP NDT and Welding certification as well. In addition we have a comprehensive network of post process NADCAP certified sub contracted suppliers located within the general area.

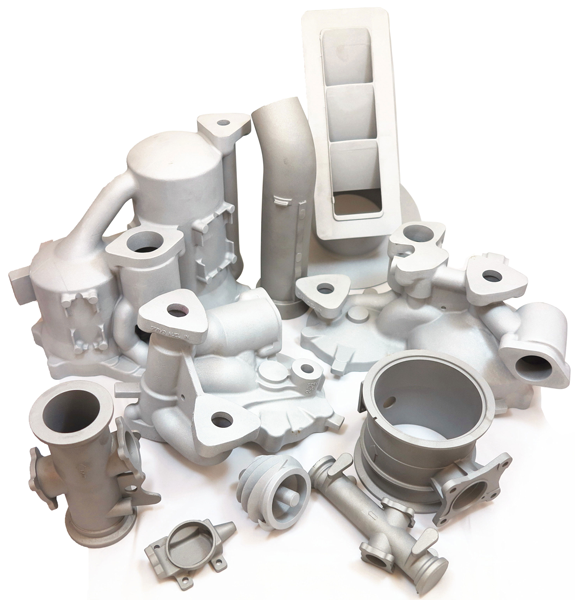

Strong Production Capabilities:

DAF employs a variety of different production capabilities so to better serve our growing and changing customer requirements. From paste to liquid wax, robotic dipping systems, ferrous, non-ferrous and vacuum melting units, automatic grinding, in house heat treat, NonDestructive testing and full CNC machining, DAF can handle most requirements in house.

We Can Inventory for You:

All products from our Asian facilities are inventoried in our Los Angeles, California warehouse and are able to be released as required by our customers. We are very flexible and able to accommodate our customers’ specific needs and customized scheduling system. We are also positioned to provide diverse sourcing options to our customers.

Optimal Supply Chain Solution:

20 years of Asia manufacturing and procurement experience secures the quality and process for our customers. Los Angeles and Shanghai based staff maintain the relationship with our manufacturing partnerships and effectively communicate with them regarding quality and engineering details, production and supply chain.