Customers Come First

Dameron Alloy Foundries provides various casting processes and brings many unique benefits to our customers, including freedom of design, reduced machining requirements, reproducibility, cost efficiency, and increased performance.

Service

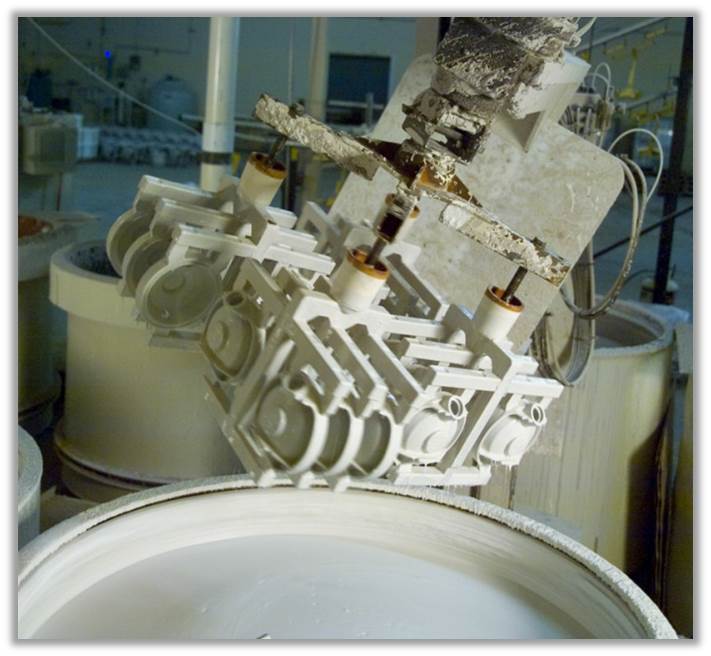

DESIGN FLEXIBILITY

The investment casting process allows the engineer design flexibility of steel or aluminum alloys, undercut and complex cored features, and none of the draft requirements common with other casting processes. We recommend consulting with Dameron prior to finalizing your design to take full advantage of the near-net-shape capabilities the process offers. In addition, rapid prototyping is available using Stereo lithography "SLA" patterns enabling design prove-out prior to building conventional tooling. The SLA process provides our customers with the ability to get your product to market faster and greatly reduces the potential for costly design changes.

REPRODUCIBILITY

The investment casting process yields superior mechanical properties, complex design capability, overall dimensional repeatability, tighter tolerances and improved surface finish when compared to competing casting technologies. As a result, the investment casting process provides the best overall value for your engineered casting design.

DISTINCTIVE CAPABILITIES

Dameron Alloy Foundries defines quality as those moments where the customers’ design and our experience converge to achieve outstanding results. Our primary responsibility is to deliver a quality product, on time every time. Our concept of value involves the assisting of alloy selection for the required end-use application, helping with the design of a new part, maintaining a technological edge and delivering a superior cast product.

TOOL CONSTRUCTION

Dameron Alloy Foundries uses both in-house capabilities and outside sources for construction of investment tooling, including wax injection dies and inspection fixtures. All tooling is manufactured using CAD software and CNC machining centers assuring the highest quality and greatest accuracy.

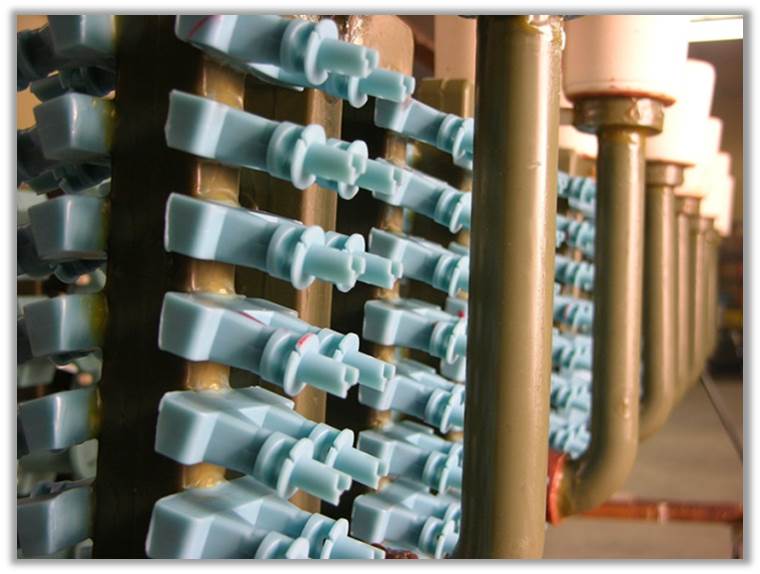

DAMERON MAINTAINED INVENTORY

Dameron Alloy Foundries quality control practices support a variety of customers needs and requirements. The company is committed to further enhancing its products and has made major investments in advanced manufacturing technology to achieve this. The DMI and KANBAN programs are an extension of this commitment allowing for stocked items and immediate shipment.

PRECISION MACHINING

Dameron Alloy Foundries is equipped with over 20 Multi-Axis CNC Machining and Turning Centers to provide "Value Added" product support for fully machined our produced castings. In addition, sub-contract- machining services are also available. Precision CMM inspection insures that customer specifications are met.

Dameron Alloy Foundries also provides an excellent and efficient option to your various needs when LCC (low cost country) procurement is required. With our decades of metal parts industry experience and our 15 years of Asia manufacturing experience, Dameron Alloy Foundries eliminates the burden of quality and delivery for our customers. The option to warehouse and release your components from our Los Angeles facility adds significant value and flexibility to substantially reduce costs.